XLPE Foam Die Cuts

XLPE foam, also known as cross-linked polyethylene foam, is a closed-cell foam that is durable and resistant to impact, water, and chemicals. One of the advantages of XLPE foam is that it can be easily shaped and cut to fit a variety of applications, making it an ideal material for die-cutting. XLPE foam die cuts are custom shapes that are cut from XLPE foam sheets using a die-cutting process. This process involves using a die, which is a specialized cutting tool, to cut out the desired shape. The foam is placed on a flat surface and the die is pressed onto it using a hydraulic press. The pressure and speed of the press are carefully controlled to ensure a clean and precise cut.

| Product Specification | ||

|---|---|---|

| Product Code | --- | |

| Density Available | 120-160 Density | |

| Shape | Customised | |

| Application | Electric Industries Automobiles Etc........... | |

| Patern | Cutomised | |

| Sample Available | 1 | |

| Certification | Available | |

| Main Demestic Market | All India | |

| Colour | Black | |

| Grades | ESD And Non ESD | |

| Third Party Confirmation | Available | |

Product Description

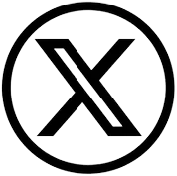

XLPE foam die cuts have a wide range of applications across various industries. One of the most common uses is in the packaging industry, where they are used to protect products during shipping and handling. The foam can be cut into custom shapes that conform to the shape of the product, providing a snug fit that prevents it from moving around in the packaging. The foam's cushioning properties also protect the product from damage caused by bumps and shocks during shipping.

XLPE foam die cuts are also used in the automotive industry, where they are used to dampen noise and vibrations. The foam is cut into custom shapes and installed in various parts of the vehicle, including the dashboard, door panels, and engine compartment. It helps to reduce the noise and vibrations that are caused by the engine and other moving parts, providing a quieter and more comfortable driving experience.

XLPE Foam Die Cuts Characteristics

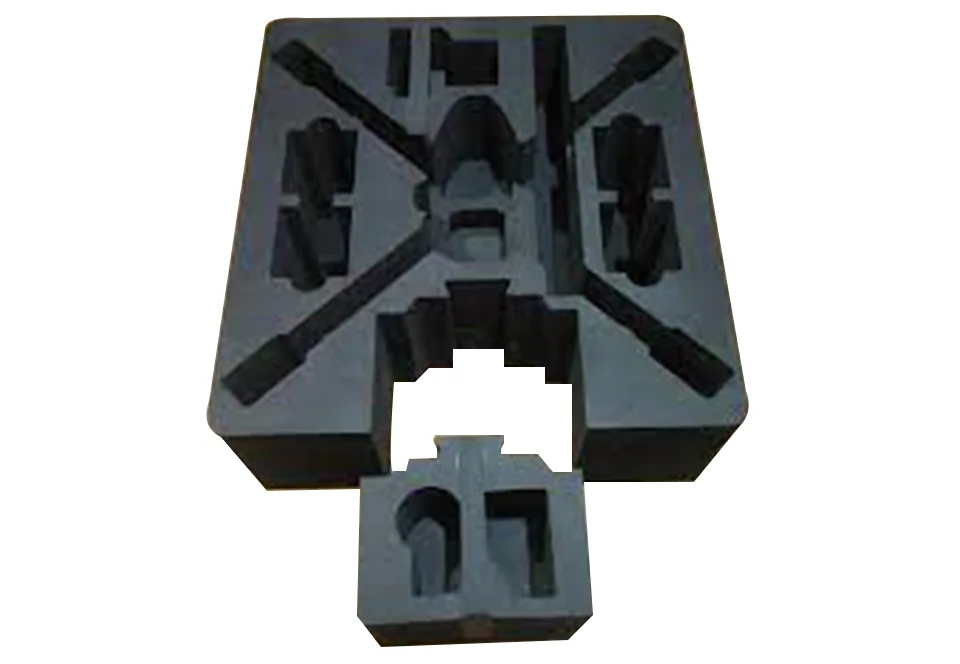

XLPE foam, also known as cross-linked polyethylene foam, is a closed-cell foam that has a unique structure that makes it highly durable and resistant to tearing, impact, and water absorption. XLPE foam die cuts are custom-cut pieces of XLPE foam that are used in various industrial applications. These die cuts are made by using a die cutting machine that precisely cuts the foam into the desired shape and size.

The characteristics of XLPE foam die cuts include high flexibility, excellent cushioning, low compression set, and resistance to chemicals, oils, and UV light. XLPE foam has a wide temperature range, making it suitable for use in both hot and cold environments. The foam is also lightweight and easy to handle, which makes it a popular choice for various applications.

XLPE foam die cuts are used in a wide range of industries, including automotive, electronics, aerospace, medical, and construction. They are used as gaskets, seals, cushioning pads, vibration dampers, insulation, and packaging materials. In the automotive industry, XLPE foam die cuts are used as gaskets and seals in engines, doors, windows, and electrical components. In the electronics industry, they are used as shock absorbers, vibration dampers, and thermal insulators. In the aerospace industry, they are used in various applications such as sound insulation, vibration isolation, and structural support. In the medical industry, XLPE foam die cuts are used in orthopedic devices, wound dressings, and prosthetic devices. In the construction industry, they are used as insulation, soundproofing, and weather stripping.

XLPE foam die cuts are available in various densities, thicknesses, and colors to suit different applications. The foam can be laminated with adhesive or other materials to enhance its performance and durability. The die cuts can be customized to different shapes, sizes, and designs to meet specific requirements.

Overall, XLPE foam die cuts offer excellent cushioning, insulation, and protection in various industrial applications. Their unique characteristics make them a versatile material that can be used in many different industries, making them a popular choice for manufacturers looking for high-performance materials for their products.

XLPE Foam Die Cuts Applications

XLPE foam die cuts are custom-made foam pieces that are cut into specific shapes and sizes for various applications. XLPE foam, or cross-linked polyethylene foam, is a closed-cell foam that is known for its durability, high strength-to-weight ratio, and excellent resistance to chemicals and water. These characteristics make it an ideal material for a wide range of applications, from packaging and insulation to gasketing and cushioning.

One of the key characteristics of XLPE foam die cuts is their versatility. They can be cut to almost any size and shape, allowing them to be used in a wide range of industries and applications. Some common shapes include circles, rectangles, squares, and triangles, but XLPE foam die cuts can also be custom cut to fit any unique application. In addition, they can be cut to various thicknesses, from thin sheets to thick blocks, depending on the specific needs of the application.

Another key characteristic of XLPE foam die cuts is their cushioning properties. XLPE foam is a highly resilient material that can compress and then return to its original shape, making it ideal for shock absorption and impact resistance. This makes it a popular material for use in packaging applications where fragile or delicate items need to be protected during transport.

XLPE foam die cuts are also highly resistant to water and chemicals, making them suitable for use in harsh environments. They can withstand exposure to many different chemicals, including acids, alkalis, and oils, without degrading or losing their structural integrity. This makes them ideal for use in applications such as chemical processing, where exposure to harsh chemicals is common.

Other common applications of XLPE foam die cuts include gasketing, insulation, and sealing. They can be used as gaskets in machinery and equipment to create a seal between two surfaces, preventing the ingress of dust, air, or other contaminants. In addition, they are often used as insulation in the construction industry, where they can help to reduce energy consumption and lower heating and cooling costs.

FAQ's

XLPE foam die cuts are custom-shaped components or pieces made from XLPE (Cross-Linked Polyethylene) foam through a die-cutting process. Die-cutting allows for precision shaping of foam for specific applications.

XLPE foam die cuts find applications in industries such as packaging, electronics, automotive, and healthcare. They are used for cushioning, insulation, and shock absorption in various products and equipment.

XLPE foam die cuts offer benefits such as excellent shock-absorbing properties, resistance to moisture and chemicals, low thermal conductivity, and the ability to be customized for specific applications.

XLPE foam die cuts are created using a die-cutting machine that uses customized cutting dies to precisely cut and shape the XLPE foam material. This process allows for consistent and accurate shapes.

Yes, XLPE foam die cuts can be fully customized in terms of shapes, sizes, thickness, and specific designs to meet the requirements of different applications and industries. Manufacturers can work with clients to create tailored foam components.