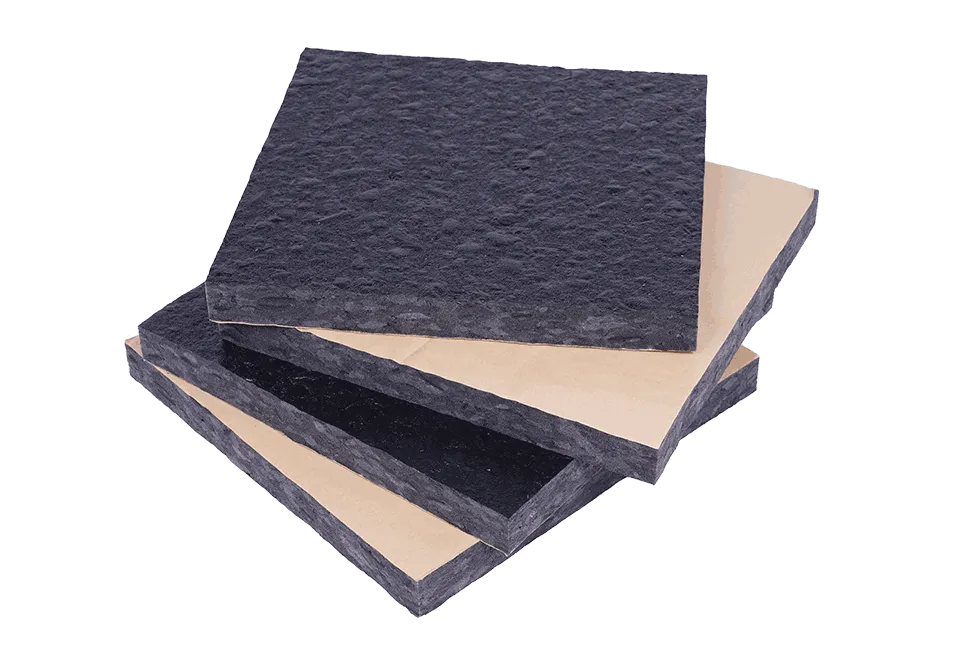

Rebonded Foams

Rebonded foam is a type of foam made from recycled foam scraps that are bonded together using a special adhesive. It is a cost-effective and environmentally friendly alternative to other types of foam materials. Rebonded foam is also incredibly versatile. It can be cut to different sizes and shapes to fit specific needs, making it ideal for a variety of uses, including carpet padding, furniture cushions, gym mats, and packaging materials.

| Product Specification | ||

|---|---|---|

| Product Code | --- | |

| Density Available | 70, 80, 90, 100, 110 Density | |

| Shape | Customised | |

| Application | Automible, Mattress, Damppings, Etc,.. | |

| Patern | Square, Convoluted, Pyramid And Customised | |

| Sample Available | 2 NOS | |

| Certification | FR Test Report | |

| Main Demestic Market | All India | |

| Colour | Black & Multi Colour | |

| Grades | FR and Non FR Grade | |

| Third Party Confirmation | Sri Ram Lab Report | |

Product Description

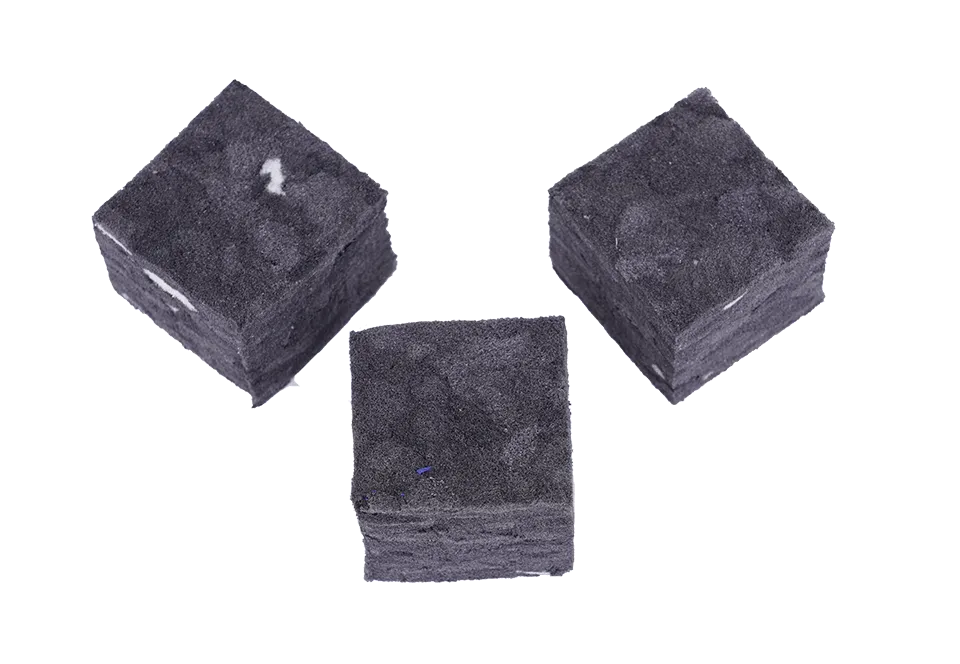

Rebonded foam is also a popular choice for sound insulation due to its high density and ability to absorb sound waves. It can be used in home theaters, recording studios, and other settings where sound quality is important. Overall, rebonded foam is a versatile and cost-effective material that has a wide range of applications. Its durability, support, and sound insulation properties make it a popular choice for many different industries. The process of making rebonded foam involves shredding foam scraps into small pieces, mixing them with a bonding agent, and compressing the mixture into large blocks. The resulting foam blocks are then cut into various sizes and shapes for use in different applications.

Rebonded Foams Characteristics

We have just seen what goes into making rebonded foams, which are often colourful foam sheets. Keeping the properties aside, rebonding foam sheets have unique characteristics, which makes them a favourite among manufacturers.

Here are some rebonding foam characteristics:

Extremely High Density: One of the strong points of rebonding foam is its high density, and can be cut into preferred thicknesses. So higher the thickness, the higher the density. This allows manufacturers to produce really dense multicolour fabric sheets.

Lightweight Build: Despite having high density, rebonding foams are extremely lightweight. The colourful rebonded foam sheets with their lightweight characteristics are another prominent feature. The lightweight build makes it easy to transport and construct end products.

Highly Versatile: Another important rebonding foam characteristic is its high versatility. It can be cut and shaped into any size and form, allowing manufacturers to produce a wide range of products. These can be sofas, mattresses, and so on.

Sound, Shock Absorbents: Foams are known to be good sound and shock absorbents. Particularly, rebonding foams are extremely good when it comes to sound and shock absorption. Manufacturers use rebonded foams as an insulating material in constructions for their high shock and sound absorbing capacity.

High Indentation Load Deflection: Every foam requires weight to create an indentation by 25 percent of its height. A higher ILD implies a firmer foam, and a rebond foam has an ILD of 7 pounds. This is another powerful characteristic of rebonding foams.

Rebonded Foams Appcliations

This brings us to non-FR foam applications in the modern world. Non-FR PU foams have diverse applications today and are used across the world. Several manufacturers have tapped into non- flame-retardant foam applications and have made them widely available and accessible.

Non-FR foams are of many kinds, including rigid and flexible ones. These foams are found in several daily items like refrigerators, plastic sheets, freezers, packaging, machinery, and much more. Non-FR PU sheets are also commonly used in the industry like electronics, appliances, and more.

More importantly, non-FR foams are commonly found in household furniture. One can find them in attresses in the form of PU foams, memory foams, spring foams, and more. Generally, non- fireproof foams are also used in upholstery like sofas and couches.

Non-FR foams are also widely used for their insulation property. For instance, polyurethane foams are used for filling voids and gaps in buildings and construction. Non-flame-resistant foams are also known to have adhesive properties, making them a construction material.

Non-fire-resistant acoustic foams are also commonly applied in the modern world. Non-FR foams are a great source to reduce high-frequency sound waves. One can also get isolation from low- requency sound waves by using thicker non-fire-resistant acoustic foams. This will further help in creating the perfect, noiseless environment.

FAQ's

Rebonded foam, also known as bonded foam, is a type of composite foam material made from recycled or scrap pieces of polyurethane foam. These foam scraps are collected, shredded, and bonded together using adhesive to create new foam sheets or blocks.

Rebonded foam is often used for various cushioning and support applications, such as in mattresses, sofa cushions, gym mats, and automotive seating. It is also utilized in packaging, soundproofing, and underlay for carpets.

Rebonded foam is cost-effective, environmentally friendly (as it recycles foam waste), and provides good support and durability. It can be customized in terms of firmness and thickness, making it suitable for a wide range of applications.

Rebonded foam is generally durable and can withstand moderate to heavy use. Its longevity depends on the quality of the adhesive used, the density of the foam, and the application. Higher-density rebonded foam tends to be more durable.

Rebonded foam is considered environmentally friendly in the sense that it recycles foam scraps that might otherwise end up in landfills. However, the adhesive used in the bonding process can vary, and some adhesives may contain chemicals that are less eco-friendly.

Rebonded foam itself is a product of recycling, as it's made from recycled foam scraps. However, recycling rebonded foam into new foam is challenging due to the adhesive used in the bonding process. Repurposing, such as using old rebonded foam for noise insulation or padding, may be more feasible.