Anti Static Foam

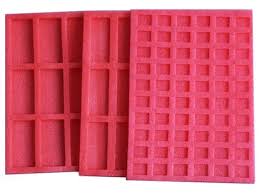

Anti-static foam is generally produced from either polyethylene or polyurethane material. Producers and manufacturers use anti-static foams for storing and transporting electronic parts and equipment. The strong foam helps protect the equipment from serious damage due to static electricity. Moreover, the foam properties also help protect products from any physical harm.

| Product Specification | ||

|---|---|---|

| Product Code | --- | |

| Density Available | 18, 24 & 28 Density | |

| Shape | Plane & Round | |

| Application | PCB Packing & Electric Parts Packing & Etc....... | |

| Patern | Convoluted, Customised | |

| Sample Available | 2 NOS | |

| Certification | ISO | |

| Main Demestic Market | All India | |

| Colour | Pink, Gray | |

| Grades | -- | |

| Third Party Confirmation | In House Certified | |

Product Description

Static energy is one of the most common energies that’s found everywhere irrespective of the climatic zone. Static energy can cause disruptions if not properly managed. This is where anti-static foam comes into the picture. Anti-static foam sheets or sprays can help keep a check on the static energy and even terminate it. For instance, you might feel a slight shock when you touch your mattress sometimes. Or you might feel a similar shock when you touch certain packaging materials. Special foams or sheets are used to terminate such energies. Anti-static foam is a special kind of foam that inhibits static electricity.

Anti Static Foam Characteristics

These foams have a few standout features that make them desirable to consumers across the world. For instance, if you search for ‘anti-static foam near me’, you’ll surely find many sellers in whichever area you are.

This is also because of its unique characteristics, which are mentioned here:

Anti-Static Feature: One of the primary features of these foams is their ability to terminate static electricity. Unlike ordinary polyurethane foams, anti-static foams are chemically treated to uphold their anti-static property.

Cushioning: Another anti-static foam characteristic is its cushioning capability. They are soft materials, which can be curated into various sizes and formats. This is what makes anti-static packaging foams.

Tear-Resistant: Anti-static foams are also tear-resistant, which is identical to other polyurethane foams. Being resistant to tears make it ideal for a wide range of applications, including rough-and-tough as well as heavy-duty applications.

Resistant to Change in Temperature: Anti-static foams are also resistant to changes in temperature. Several factors can impact foams, including temperature conditions like humidity. But anti-static foams are developed to be non-reactive to changes in temperature, especially humidity.

Anti Static Foam Applications

Anti-static foam is a specialized type of foam that is designed to dissipate static electricity and prevent electrostatic discharge. It is commonly used in a variety of applications where static electricity can cause damage to sensitive electronic components.

One of the most common applications of anti-static foam is in the packaging of electronic components. Anti-static foam can be used to create custom-fit packaging that protects electronic components during transportation and storage. The foam helps to dissipate any static electricity that may build up, preventing damage to the components.

Anti-static foam is also used in the manufacturing of electronic devices. During the manufacturing process, static electricity can build up on equipment and work surfaces, which can damage sensitive components. Anti-static foam is used as a work surface to help prevent static buildup and protect the components.

Another application of anti-static foam is in the construction of cleanrooms. Cleanrooms are used in industries such as pharmaceuticals, biotechnology, and electronics manufacturing to maintain a controlled environment that is free from contaminants. Anti-static foam is used to create walls, floors, and ceilings in cleanrooms to help prevent static buildup and maintain the integrity of the cleanroom environment.

In summary, anti-static foam is a versatile material that is used in a variety of applications where static electricity can cause damage to sensitive electronic components. From packaging to manufacturing to cleanroom construction, anti-static foam helps to ensure the safety and reliability of electronic devices and equipment.

FAQ's

Anti-static foam is a specialized material designed to prevent the buildup and discharge of static electricity. It is used to protect sensitive electronic components from electrostatic damage in storage, shipping, and packaging applications.

Anti-static foam and ESD foam both serve to prevent electrostatic damage, but anti-static foam focuses on dissipating static charges gradually, whereas ESD foam provides more robust protection against rapid electrostatic discharges.

Anti-static foam is essential for electronic components and devices because it helps safeguard against electrostatic discharge, which can damage or destroy sensitive parts, leading to costly failures and malfunctions.

Anti-static foam is commonly used in the electronics industry for packaging and storage of sensitive electronic components, including integrated circuits (ICs), computer chips, and other devices prone to ESD damage.

Anti-static foam incorporates conductive materials that allow the gradual dissipation of static charges, ensuring that any potential electrostatic discharges are minimized. This protects the enclosed electronic components.

Yes, anti-static foam can be customized to meet specific packaging requirements. This may involve selecting the appropriate foam thickness, shape, and size to fit the components while ensuring effective anti-static protection.