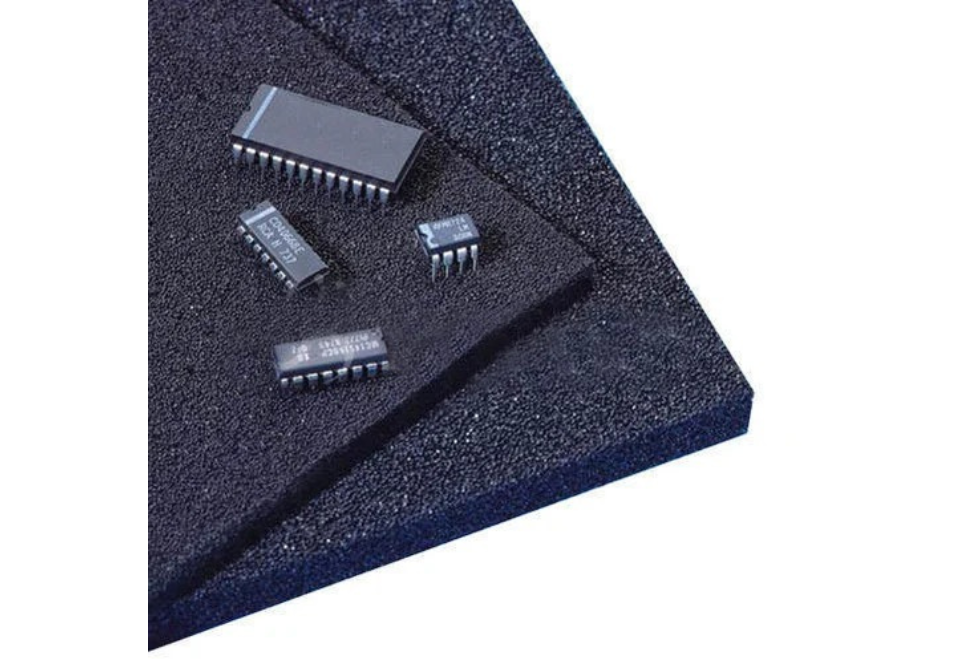

Conductivity Foam

Conductivity foam refers to a specialized type of foam material engineered to possess conductive properties, allowing it to conduct electrical or thermal energy. The foam is designed to provide a balance between flexibility, compressibility, and electrical conductivity. This unique combination of properties makes it suitable for various applications across different industries.

| Product Specification | ||

|---|---|---|

| Product Code | --- | |

| Density Available | ---- | |

| Shape | --- | |

| Application | --- | |

| Patern | --- | |

| Sample Available | --- | |

| Certification | --- | |

| Main Demestic Market | --- | |

| Colour | --- | |

| Grades | --- | |

| Third Party Confirmation | --- | |

Product Description

In electronics, conductivity foam is often used for electromagnetic interference (EMI) and radio frequency interference (RFI) shielding. It helps in preventing unwanted electromagnetic signals from interfering with sensitive electronic components. The foam acts as a barrier, absorbing and dissipating electromagnetic energy.

Moreover, in thermal management applications, conductivity foam can be employed to enhance heat transfer. By incorporating thermally conductive materials into the foam, it becomes an effective means to dissipate heat from electronic devices, thereby preventing overheating and ensuring optimal performance.

In addition to electronics, conductivity foam finds applications in industries such as aerospace, automotive, and medical devices. Its versatility makes it useful for gasketing, sealing, and padding in various components where both electrical conductivity and flexibility are crucial.

The specific composition of conductivity foam can vary, with materials such as carbon, graphite, or metal particles often added to achieve the desired conductive properties. This makes conductivity foam a valuable material for applications where both electrical and thermal management properties are essential.

Properties

Conductivity foam, prized for its unique combination of flexibility, compressibility, and electrical conductivity, possesses several key properties that make it valuable across diverse industries. Here's an exploration of the essential properties of conductivity foam:

- Electrical Conductivity: Conductivity foam is specifically engineered to be electrically conductive. This property makes it highly effective for applications requiring EMI and RFI shielding in electronics. It can divert and absorb electromagnetic interference, safeguarding sensitive electronic components from unwanted signals.

- Thermal Conductivity: In addition to electrical conductivity, conductivity foam can exhibit thermal conductivity. This property makes it useful for thermal management applications. By facilitating the efficient transfer of heat away from electronic devices, conductivity foam helps prevent overheating, ensuring optimal performance and longevity.

Conductivity:

- Additives: The conductivity in foam is often achieved through the incorporation of conductive materials. Common additives include carbon fibers, graphite, or metal particles. These materials enhance the foam's ability to conduct electricity and heat.

- Variability: The composition of conductivity foam can be tailored to meet specific application requirements. Different formulations and ratios of conductive materials can be used to achieve desired levels of conductivity and other properties.

Material Composition:

- Flexibility: Conductivity foam is typically flexible, allowing it to conform to irregular surfaces. This flexibility makes it suitable for applications where a conformable and adaptable material is required.

- Compressibility: The foam is often compressible, meaning it can be easily compressed or deformed under pressure and then return to its original shape. This property is beneficial for creating effective seals and gaskets in various applications.

Flexibility and Compressibility:

- Applications: Conductivity foam finds versatile applications across industries such as electronics, aerospace, automotive, and medical devices. It is used in gasketing, sealing, padding, and other applications where both electrical conductivity and flexibility are essential.

- Customization: The material can be customized to meet specific requirements, adjusting its composition, thickness, and other parameters to suit the needs of a particular application.

Versatility:

- EMI/RFI Shielding: One of the primary applications of conductivity foam is in providing effective EMI and RFI shielding. The foam acts as a barrier, preventing electromagnetic signals from interfering with electronic devices.

Shielding Effectiveness:

- Resistance: Conductivity foam is designed to be durable and resistant to wear and tear. This is crucial for its long-term performance in demanding environments.

Durability:

- Lightweight: Depending on its specific composition, conductivity foam can be lightweight. This characteristic is particularly important in applications where weight is a critical factor, such as in aerospace components.

Weight Considerations:

In summary, conductivity foam's unique properties make it a valuable material for applications requiring a combination of electrical conductivity, thermal management, flexibility, and adaptability. Its versatility and customizability contribute to its widespread use in various industries for diverse applications.

Characteristics

Conductivity foam exhibits a set of distinctive characteristics that make it a valuable material in various applications, particularly in electronics, aerospace, automotive, and other industries where electrical and thermal management properties are critical.

- High Conductivity: One of the primary characteristics of conductivity foam is its ability to conduct electricity. This property is crucial for its application in EMI and RFI shielding in electronic devices, preventing interference and maintaining signal integrity.

Electrical Conductivity:

- Efficient Heat Transfer: Conductivity foam often possesses thermal conductivity, allowing it to efficiently transfer heat. This property is essential for thermal management applications, helping dissipate heat from electronic components to prevent overheating.

Thermal Conductivity:

- EMI/RFI Shielding:One of the primary applications of conductivity foam is in providing effective electromagnetic interference (EMI) and radiofrequency interference (RFI) shielding. The foam acts as a barrier, preventing unwanted electromagnetic signals from affecting electronic devices.

Shielding Effectiveness:

- Low Density: Depending on its specific formulation, conductivity foam can be lightweight. This characteristic is crucial in applications where minimizing weight is important, such as in aerospace components.

Lightweight:

Applications

Conductivity foam, with its unique combination of electrical conductivity, thermal management capabilities, flexibility, and adaptability, finds a wide array of applications across various industries. Here is an exploration of the diverse applications of conductivity foam:

- EMI/RFI Shielding:Conductivity foam is extensively used in electronics and telecommunications equipment for electromagnetic interference (EMI) and radiofrequency interference (RFI) shielding. It helps prevent unwanted electromagnetic signals from interfering with sensitive electronic components, ensuring the reliability and integrity of signals.

- Electronic Enclosures: It is employed in the construction of electronic enclosures to create a conductive barrier, shielding internal components from external interference.

- Printed Circuit Board (PCB) Components: Conductivity foam is utilized in the construction of PCBs and other electronic components to manage electromagnetic interference and prevent signal degradation.

Electronics and Telecommunications:

- Antenna Systems:Conductivity foam is used in antenna systems to control electromagnetic interference and ensure the accuracy and efficiency of communication systems in aerospace applications.

- Satellite Equipment:In the construction of satellite equipment, conductivity foam aids in managing heat generated by electronic components and offers effective shielding against external electromagnetic influences.

- Avionics:It is employed in avionics systems to shield sensitive electronic components from electromagnetic interference, ensuring the safety and reliability of aircraft systems.

Aerospace Industry:

- Electronic Control Units (ECUs):In modern vehicles, ECUs and other electronic components generate heat. Conductivity foam is used for thermal management to dissipate heat effectively, ensuring optimal performance and longevity of automotive electronics.

- Wireless Communication Systems:Conductivity foam is applied in automotive wireless communication systems to manage electromagnetic interference, ensuring reliable connectivity and communication.

Automotive Sector:

- MRI Machines:In medical devices like MRI machines, where precision is critical, conductivity foam helps manage heat generated during operation and shields sensitive electronics from electromagnetic interference.

- Monitoring Equipment: Conductivity foam is employed in various medical monitoring equipment to provide EMI shielding and maintain the accuracy of data collected.

Medical Devices:

- Control Systems:In industrial settings, conductivity foam is used in control systems and electronic equipment to manage heat and shield against electromagnetic interference, ensuring the smooth operation of machinery.

- Process Control Instruments:Conductivity foam finds applications in instruments used for process control in industries, providing thermal management and shielding against EMI.

Industrial Electronics:

- Radar Systems:In radar systems and electronic warfare equipment, conductivity foam plays a crucial role in managing heat and shielding against electromagnetic interference for accurate signal processing.

- Communication Systems: It is used in military communication systems to ensure secure and interference-free communication in challenging environments.

Military and Defense:

- Mobile Phones: In mobile phones and other portable electronic devices, conductivity foam aids in thermal management, preventing overheating during prolonged use.

- Wearable Devices: For wearable electronic devices, where flexibility and comfort are crucial, conductivity foam provides thermal management and shielding properties without compromising on form factor.

Consumer Electronics:

- Test and Measurement Equipment:In laboratories and research facilities, conductivity foam is utilized in test and measurement equipment to create controlled environments for accurate testing and experimentation.

- Prototype Development: During the prototyping phase of electronic devices, conductivity foam assists in managing heat and shielding against interference, allowing for reliable testing and refinement.

- Customization:

Research and Development:

- Solar Inverters:In solar energy systems, conductivity foam is applied in inverters to manage heat generated during the conversion process, ensuring the efficiency and reliability of the system.

- Wind Turbine Controls:For electronic components in wind turbine controls, conductivity foam provides thermal management and shields against electromagnetic interference in demanding environmental conditions.

Renewable Energy::

In conclusion, conductivity foam is a versatile material with applications spanning across industries where electrical conductivity, thermal management, flexibility, and shielding properties are crucial. Its ability to address diverse needs makes it an indispensable component in the design and performance optimization of a wide range of electronic devices and systems.